What is a sand pump?

A sand pump is a specialized type of pump used for transferring and handling sand, slurry, and other abrasive materials. It is an essential piece of equipment in various industries, including construction, mining, dredging, and oil and gas, where the movement of sand and similar materials is a common requirement. This article delves into the workings, applications, and advantages of sand pumps, as well as the solutions offered by PEARL Pump, a leading sand pump supplier in China that supports customization.

How Does a Sand Pump Work?

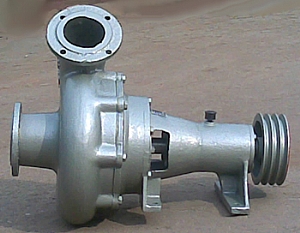

A sand pump operates by creating a vacuum or using centrifugal force to move sand and slurry through a pipeline. There are different types of sand pumps, including centrifugal sand pumps, submersible sand pumps, and horizontal sand pumps, each designed for specific applications. The general working principle involves:

Suction: The pump creates a vacuum or uses an impeller to draw sand and slurry into the pump.

Transfer: The sand and slurry are then pushed through the pump’s discharge outlet and into the designated pipeline or container.

Discharge: The material is expelled from the pump with sufficient force to ensure efficient transfer over the required distance.

The components of a sand pump, such as the impeller, casing, and wear plates, are typically made from wear-resistant materials to withstand the abrasive nature of the materials being pumped.

Applications of Sand Pumps

Sand pumps are used in a wide range of industries and applications, including:

Construction: Sand pumps are used to move sand, gravel, and slurry for building foundations, tunneling, and other construction projects.

Mining: In mining operations, sand pumps are essential for transporting mined materials, especially in the processing of ores.

Dredging: Dredging operations use sand pumps to remove sediment from waterways, harbors, and channels to maintain navigable depths.

Oil and Gas: Sand pumps are used in the oil and gas industry to handle drilling mud and to transport sand used in hydraulic fracturing.

Environmental Projects: Sand pumps are also employed in environmental projects, such as beach reclamation and erosion control, where large volumes of sand need to be moved.

Advantages of Sand Pumps

Efficiency: Sand pumps are designed to handle large volumes of abrasive materials efficiently, reducing the time and labor required for manual handling.

Durability: Constructed from wear-resistant materials, sand pumps are built to last, even in harsh and abrasive environments.

Versatility: With different types of sand pumps available, they can be used in various applications, from construction and mining to dredging and environmental projects.

Cost-Effective: By improving the efficiency and speed of material handling, sand pumps can significantly reduce operational costs.

Challenges and Considerations

While sand pumps offer numerous benefits, there are also some challenges to consider:

Wear and Tear: Despite being made from wear-resistant materials, sand pumps can still experience significant wear and tear due to the abrasive nature of the materials they handle. Regular maintenance and component replacement are necessary.

Clogging: Sand and slurry can sometimes clog the pump, leading to downtime and maintenance issues. Proper pump selection and regular maintenance can help mitigate this problem.

Energy Consumption: Depending on the type and application, sand pumps can be energy-intensive. It’s important to choose an energy-efficient model to minimize operational costs.

PEARL Pump: Your Sand Pump Solution Provider

PEARL Pump is a renowned sand pump supplier in China, offering a wide range of high-quality, customizable sand pumps to meet various industrial needs. Our sand pumps are designed to handle the most challenging applications, ensuring reliability and efficiency.

Customization Support: At PEARL Pump, we understand that each project has unique requirements. We offer customization options to tailor our sand pumps to your specific needs.

High-Quality Materials: Our sand pumps are constructed using the highest quality materials to ensure durability and longevity, even in the most abrasive environments.

Comprehensive Solutions: From consultation and design to installation and maintenance, PEARL Pump provides end-to-end solutions to ensure your sand pumping operations run smoothly.

For more information and to discuss your specific sand pump requirements, please contact us:

PEARL Pump China Sand Pump Supplier

Support Customization

Skype: +8615013488376

WhatsApp: +8615013488376

Email: shangzhengze@gmail.com

Conclusion

Sand pumps play a critical role in various industries by efficiently handling and transferring abrasive materials like sand and slurry. Their applications range from construction and mining to dredging and environmental projects. While they offer numerous benefits, including efficiency, durability, and versatility, regular maintenance and proper pump selection are essential to address challenges such as wear and tear and clogging.

PEARL Pump stands out as a leading sand pump supplier in China, offering high-quality, customizable solutions to meet the specific needs of our clients. With our expertise and comprehensive support, we ensure that your sand pumping operations are efficient and reliable, helping you achieve your project goals.

- What is the purpose of a screw pump?[ 2024-04-26 ]

- What are the 3 major types of chemical pumps used?[ 2023-07-15 ]

- What is the main advantage of submersible pump?[ 2024-05-18 ]

- What two functions does a vacuum pump perform?[ 2024-05-01 ]

- What is the difference between a lift station and a pump station?[ 2024-05-08 ]

- What kind of pumps are used in oil pipelines?[ 2024-04-11 ]

- What is the design life of a pumping station?[ 2024-06-13 ]

- What is the difference between drainage pump and sewage pump?[ 2024-04-09 ]

- What are the three types of pump?[ 2024-04-09 ]

- diaphragm vs impeller pump[ 2024-05-04 ]