What pumps do chemical industry use?

Pumps Used in the Chemical Industry

The chemical industry is a vital sector that encompasses the production of chemicals and related products, including pharmaceuticals, petrochemicals, and food additives. This industry requires pumps capable of handling aggressive, corrosive, and hazardous substances with precision and safety. Various types of pumps are used in chemical processes, each designed to meet specific needs and challenges. In this article, we will explore the primary types of pumps used in the chemical industry, their features, advantages, and applications. Additionally, we will introduce PEARL Pump, a leading supplier of chemical pumps in China, offering customized solutions to meet diverse industrial needs.

Types of Pumps Used in the Chemical Industry

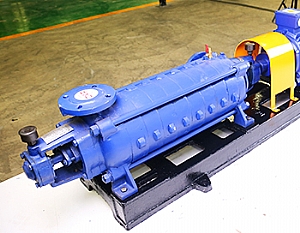

Centrifugal Pumps

Overview: Centrifugal pumps are widely used in the chemical industry for their ability to handle large volumes of liquids at relatively low pressures. They operate by converting rotational kinetic energy into hydrodynamic energy to move fluids.

Features: These pumps are available in various materials such as stainless steel, plastic, and specialty alloys to resist corrosion and handle aggressive chemicals.

Advantages: Centrifugal pumps are known for their high efficiency, simple design, and ease of maintenance. They are suitable for transferring low-viscosity fluids.

Applications: They are commonly used for water treatment, transferring chemicals in bulk, and in cooling and heating systems within chemical plants.

Diaphragm Pumps

Overview: Diaphragm pumps, also known as membrane pumps, use a flexible diaphragm that reciprocates to create a pumping action. This design ensures that the fluid is contained within the diaphragm, preventing leaks.

Features: These pumps are available in both electric and air-operated models, with various diaphragm materials to handle different chemical compatibilities.

Advantages: Diaphragm pumps are highly versatile and can handle both high-viscosity and low-viscosity fluids, including those with suspended solids. They offer excellent chemical resistance and are ideal for hazardous or corrosive fluids.

Applications: Typical applications include transferring acids, bases, solvents, and viscous liquids in industries such as pharmaceuticals, food and beverage, and wastewater treatment.

Peristaltic Pumps

Overview: Peristaltic pumps, also known as hose pumps, operate by compressing and releasing a flexible tube or hose to move the fluid. This design ensures that the fluid only contacts the inside of the tube, making it suitable for sensitive and corrosive chemicals.

Features: These pumps can handle a wide range of fluid viscosities and are available in various tube materials to ensure chemical compatibility.

Advantages: Peristaltic pumps are known for their gentle pumping action, making them suitable for shear-sensitive fluids. They also provide a high degree of precision and control, which is essential in dosing and metering applications.

Applications: Common applications include chemical dosing, fluid transfer in laboratories, and handling slurries and viscous liquids in the chemical and food industries.

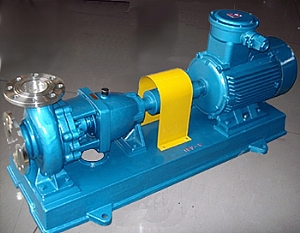

Magnetic Drive Pumps

Overview: Magnetic drive pumps, or mag-drive pumps, use a magnetic coupling to transfer torque from the motor to the pump without a direct mechanical connection. This design eliminates the need for a seal, reducing the risk of leaks.

Features: These pumps are typically made from corrosion-resistant materials such as stainless steel, plastic, and specialty alloys to handle aggressive chemicals.

Advantages: Magnetic drive pumps offer excellent chemical resistance, high efficiency, and minimal maintenance. The seal-less design makes them ideal for handling hazardous and volatile chemicals.

Applications: They are commonly used in chemical processing, pharmaceutical manufacturing, and applications where leak prevention is critical.

Gear Pumps

Overview: Gear pumps are positive displacement pumps that use meshing gears to move the fluid. They are known for their ability to handle viscous fluids and provide a steady, pulseless flow.

Features: These pumps are available in various materials, including stainless steel and plastic, to ensure compatibility with different chemicals.

Advantages: Gear pumps are highly efficient, reliable, and capable of handling high-viscosity fluids and high-pressure applications

. They offer precise flow control and are ideal for metering and dosing applications.

Applications: Typical applications include transferring adhesives, polymers, resins, and other viscous chemicals in industries such as chemical processing, oil and gas, and food production.

Peristaltic Pumps

Overview: Peristaltic pumps, also known as hose pumps, use rollers or shoes to compress a flexible tube, creating a vacuum that draws fluid into the tube and propels it forward. This design ensures that the fluid only contacts the inside of the tube, making it suitable for sensitive and corrosive chemicals.

Features: These pumps can handle a wide range of fluid viscosities and are available in various tube materials to ensure chemical compatibility.

Advantages: Peristaltic pumps are known for their gentle pumping action, making them suitable for shear-sensitive fluids. They also provide a high degree of precision and control, which is essential in dosing and metering applications.

Applications: Common applications include chemical dosing, fluid transfer in laboratories, and handling slurries and viscous liquids in the chemical and food industries.

Screw Pumps

Overview: Screw pumps are positive displacement pumps that use one or more screws to move fluid along the screw's axis. They are particularly effective at handling viscous fluids and those containing solid particles.

Features: These pumps can handle a wide range of viscosities and can be made from materials that resist corrosion and abrasion.

Advantages: Screw pumps provide a smooth, non-pulsating flow and are capable of handling high-viscosity fluids. They are also efficient in handling abrasive and slurry-type fluids.

Applications: They are used in transferring oils, viscous chemicals, and slurries in industries like petrochemical, food processing, and wastewater treatment.

Piston Pumps

Overview: Piston pumps are positive displacement pumps that use a piston to move fluids. These pumps are known for their ability to handle very high pressures.

Features: Piston pumps are robust and can handle a variety of fluids, including abrasive and high-viscosity materials.

Advantages: These pumps provide precise control over fluid delivery and can handle high-pressure applications. They are also capable of handling high-viscosity fluids.

Applications: Piston pumps are used in high-pressure cleaning, chemical injection, and hydraulic applications within the chemical industry.

PEARL Pump: Your Trusted Chemical Pump Supplier

As a leading supplier of chemical pumps in China, PEARL Pump offers a wide range of high-quality, customizable solutions designed to meet the diverse needs of various industries. Our commitment to excellence ensures that our chemical pumps provide reliable performance, durability, and efficiency.

Customizable Solutions

PEARL Pump provides a range of chemical pumps that can be tailored to meet specific requirements. Whether you need a pump for handling corrosive acids, viscous polymers, or precise chemical dosing, we have the expertise to deliver the right solution.

Quality and Reliability

Our chemical pumps are manufactured using high-quality materials and advanced technology, ensuring durability and long-term performance. Each pump undergoes rigorous testing to meet our stringent quality standards.

Support and Service

PEARL Pump offers comprehensive support and service to our clients, from initial consultation and installation to ongoing maintenance and troubleshooting. Our team of experts is always available to assist you in finding the right pumping solution and ensuring it operates efficiently.

For more information on our chemical pumps and to inquire about customizable solutions, please contact us:

PEARL Pump China Chemical Pump SupplierSkype: +8615013488376

Whatsapp: +8615013488376

Email: shangzhengze@gmail.com

Conclusion

Selecting the right pump for chemical transfer is crucial to ensure safe, efficient, and reliable handling of aggressive and corrosive fluids. The choice of pump depends on the specific requirements of the application, including the type of chemical, fluid viscosity, flow rate, and pressure. Centrifugal pumps, diaphragm pumps, peristaltic pumps, magnetic drive pumps, and gear pumps each offer unique advantages and are suitable for different chemical transfer needs.

Understanding the features and benefits of each type of pump helps in making an informed decision that meets the specific demands of your process. Despite their higher initial cost and maintenance requirements, the long-term benefits and robust performance of these pumps make them a valuable investment.

PEARL Pump, as a trusted supplier of chemical pumps in China, offers customizable solutions that ensure reliable performance and efficiency. Our commitment to quality, customer service, and support makes us the preferred choice for chemical pumping solutions.

- Is fire pump a centrifugal pump?[ 2024-05-29 ]

- What is submersible pump used for?[ 2024-04-12 ]

- Do I need a sewage pump or sump pump?[ 2024-04-09 ]

- What is a mud pump used for?[ 2024-05-21 ]

- What is the most commonly used pump for lifting sewage?[ 2024-05-09 ]

- What is the difference between high pressure and low pressure pumps?[ 2024-05-23 ]

- What are the three types of pump?[ 2024-04-09 ]

- Who is the largest pump manufacturer in china?[ 2024-04-09 ]

- How do you size a pump station?[ 2024-06-05 ]

- What are the disadvantages of self priming pumps?[ 2024-04-11 ]