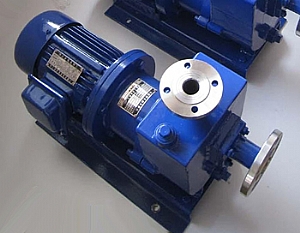

What is a magnetic pump?

A magnetic pump, also known as a magnetic drive pump or mag-drive pump, is a type of pump that uses magnetic coupling to transfer torque from the motor to the pump impeller without any direct mechanical connection. This unique design eliminates the need for a shaft seal, reducing the risk of fluid leakage and contamination. Magnetic pumps are widely used in various industries due to their efficiency, reliability, and ability to handle hazardous or corrosive fluids.

How a Magnetic Pump Works

In a magnetic pump, the motor drives an outer magnet, which is connected to an impeller housed within a pump chamber. Inside the pump, there is an inner magnet attached to the impeller. The outer magnet and inner magnet are separated by a containment shell made of a non-magnetic material. When the motor runs, the outer magnet creates a magnetic field that drives the inner magnet, causing the impeller to rotate and pump fluid through the chamber.

The lack of a direct mechanical connection between the motor and the impeller allows the pump to operate without a mechanical seal. This design not only minimizes the risk of fluid leakage but also reduces maintenance requirements.

Advantages of Magnetic Pumps

Leakage-Free Operation

Since there is no shaft seal, magnetic pumps operate without the risk of fluid leakage. This is particularly important when handling hazardous, toxic, or corrosive fluids.Reduced Maintenance

Magnetic pumps have fewer moving parts and no mechanical seals, reducing the need for maintenance and extending the pump's lifespan.High Efficiency

Magnetic pumps offer high efficiency and energy savings due to their design and operation.Corrosion Resistance

Magnetic pumps are often made with corrosion-resistant materials, making them suitable for handling corrosive fluids.Compact Design

Magnetic pumps have a compact and simple design, making them easy to install and integrate into existing systems.Low Noise and Vibration

The design of magnetic pumps results in low noise and vibration levels, providing a quieter and smoother operation.Applications of Magnetic Pumps

Chemical Industry

Magnetic pumps are widely used in the chemical industry to handle corrosive and hazardous fluids such as acids, bases, and solvents.Pharmaceutical Industry

Magnetic pumps are used in the pharmaceutical industry for transferring and dosing sensitive and high-purity liquids.Petrochemical Industry

Magnetic pumps are used for pumping hydrocarbons and other petrochemical fluids while minimizing the risk of leaks.Food and Beverage Industry

Magnetic pumps are used for transferring and dosing food-grade liquids while maintaining sanitary conditions.Water Treatment

Magnetic pumps are used in water treatment plants for dosing and transferring chemicals and additives.Electronics Manufacturing

Magnetic pumps are used for handling etching and cleaning fluids in electronics manufacturing processes.Conclusion

Magnetic pumps offer a reliable and efficient solution for handling various types of fluids in different industries. Their leakage-free operation, reduced maintenance requirements, and corrosion resistance make them a preferred choice for applications involving hazardous or corrosive fluids. PEARL Pump, a leading supplier of magnetic pumps in China, provides high-quality magnetic pumps designed to meet the needs of diverse industries. If you require a reliable and efficient magnetic pump for your operations, consider PEARL Pump as your trusted supplier.

- What is an industrial pump?[ 2024-04-09 ]

- What is a self-priming pump?[ 2024-04-15 ]

- What is the difference between a fire pump and a normal pump?[ 2024-04-25 ]

- What is used to supply water?[ 2024-04-10 ]

- What fluids can industrial pumps handle?[ 2024-04-15 ]

- Which pump is best for municipal water?[ 2024-06-12 ]

- What strength water pump do I need?[ 2024-05-10 ]

- Why do you need a pumping station?[ 2024-06-14 ]

- How do you treat a private water supply?[ 2024-04-10 ]

- What are the basics of a pump station?[ 2024-06-14 ]