What is an industrial pump?

Understanding Industrial Pumps: Powering Industries Worldwide

Industrial pumps are essential components in various sectors, driving the movement of liquids and gases to facilitate industrial processes. These pumps play a crucial role in industries such as manufacturing, oil and gas, mining, agriculture, water treatment, and many others. They are responsible for tasks ranging from transferring fluids between different stages of a process to maintaining pressure in pipelines and controlling flow rates.

Types of Industrial Pumps:

There are several types of industrial pumps, each designed for specific applications and operating conditions:

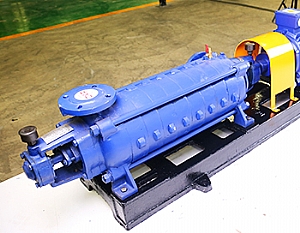

Centrifugal Pumps:

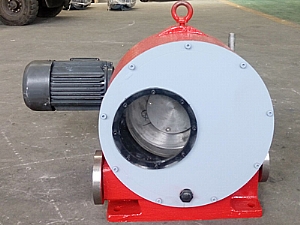

These pumps use centrifugal force to move fluid through a piping system. They are widely used for water supply, wastewater treatment, and HVAC systems due to their simple design and efficiency.Positive Displacement Pumps:

Unlike centrifugal pumps, positive displacement pumps move fluid by trapping a fixed volume and forcing it through the discharge pipe. Examples include gear pumps, piston pumps, and diaphragm pumps, which are suitable for applications requiring high pressure and precise flow control.Submersible Pumps:

These pumps are designed to be submerged in the fluid they are pumping, making them ideal for applications such as drainage, sewage pumping, and groundwater extraction. They are often used in construction, mining, and municipal wastewater systems.Reciprocating Pumps:

Reciprocating pumps use a piston or plunger to create a vacuum that draws fluid into a cylinder and then forces it out through a discharge valve. These pumps are commonly found in high-pressure applications like hydraulic systems, oil and gas extraction, and chemical processing.Industrial pumps offer numerous benefits to industries worldwide, including:

Increased Efficiency:

By automating fluid transfer processes, industrial pumps improve efficiency and productivity, reducing manual labor and operating costs.Enhanced Reliability:

Modern industrial pumps are designed for durability and reliability, minimizing downtime and maintenance requirements, thus ensuring uninterrupted operations.Versatility:

Industrial pumps are available in various sizes, configurations, and materials to suit a wide range of applications, from small-scale operations to large industrial complexes.Cost-Effectiveness:

While high-quality industrial pumps may come with a significant initial investment, their long-term benefits, including improved productivity and reduced energy consumption, often outweigh the upfront costs.Chinese Industrial Pumps:

In China, the industrial pump market offers a wide range of products at competitive prices. With the country's robust manufacturing capabilities and vast network of suppliers, Chinese industrial pumps are known for their affordability without compromising quality. This makes them a popular choice for industries worldwide seeking cost-effective solutions for their fluid handling needs.

In conclusion, industrial pumps are indispensable tools that drive the efficiency, productivity, and reliability of various industrial processes. With advancements in technology and manufacturing, coupled with competitive pricing in markets like China, industrial pumps continue to play a vital role in powering industries worldwide.

- What is the difference between a gear pump and a screw pump?[ 2024-04-26 ]

- What is a vacuum pump used for?[ 2024-05-01 ]

- How long does it take to build a pump station?[ 2024-06-05 ]

- What is a mud pump used for?[ 2024-05-21 ]

- What is the most commonly used pump for lifting sewage?[ 2024-05-09 ]

- Is a filter pump better than a sand pump?[ 2024-05-30 ]

- What are the three types of pump?[ 2024-04-09 ]

- What does a diesel water pump do?[ 2024-05-10 ]

- How do you size a pump station?[ 2024-06-05 ]

- What is a flood pumping station?[ 2024-05-08 ]