How does an industrial pump work?

Industrial pumps are essential components in various industries, playing a crucial role in the transportation of fluids, including water, chemicals, oil, and wastewater. As a leading supplier in China, PEARL Pump provides high-quality industrial pumps that are vital for the smooth operation of many industrial processes.

At its core, an industrial pump operates by converting mechanical energy into hydraulic energy to move fluids from one location to another. These pumps come in different types and designs, each suited for specific applications and operating conditions.

Centrifugal pumps, one of the most common types, work by using centrifugal force to propel fluid outward from the pump's rotating impeller. As the impeller spins, it creates a low-pressure zone at the center, causing fluid to flow into the pump's suction inlet. The fluid is then accelerated and pushed outward by the spinning impeller, increasing its velocity and pressure before being discharged through the pump's outlet.

Positive displacement pumps, on the other hand, operate by trapping and displacing a fixed volume of fluid with each cycle of operation. These pumps use reciprocating or rotating mechanisms to create suction and discharge pressure, making them suitable for handling viscous fluids and applications requiring precise flow control.

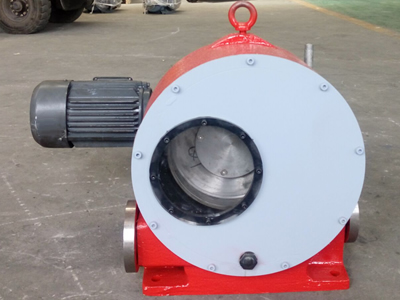

The operation of an industrial pump typically involves several key components, including the pump housing, impeller or rotor, suction and discharge ports, and motor or drive unit. The pump housing, often made of durable materials like cast iron or stainless steel, encloses the internal components and provides support and stability during operation.

The impeller, located inside the pump housing, is responsible for generating the necessary fluid flow and pressure. Depending on the pump type and application, the impeller may feature different designs, such as open, closed, or semi-open, to accommodate varying fluid viscosities and particle sizes.

The suction and discharge ports, located at opposite ends of the pump housing, facilitate the entry and exit of fluid into and out of the pump. These ports are connected to piping systems that transport the fluid to its intended destination, whether it's a storage tank, processing vessel, or distribution network.

Lastly, the motor or drive unit provides the necessary power to drive the pump's operation. Electric motors are commonly used in industrial pumps, though other types of drives, such as diesel engines or hydraulic motors, may also be employed depending on the application requirements.

In conclusion, industrial pumps are vital components in various industries, enabling the efficient transport of fluids for processing, distribution, and other applications. As a leading supplier in China, PEARL Pump offers a wide range of high-quality industrial pumps designed to meet the diverse needs of its customers, ensuring reliable performance and optimal efficiency in industrial processes.

- Who is the largest pump manufacturer in china?[ 2024-04-09 ]

- How much does it cost to build a pump station? [ 2024-05-08 ]

- What are the basics of a pump station?[ 2024-06-14 ]

- What is the difference between self-priming and non priming pumps?[ 2024-04-11 ]

- Is a filter pump better than a sand pump?[ 2024-05-30 ]

- What are the disadvantages of self priming pumps?[ 2024-04-11 ]

- What is the difference between magnetic pump and centrifugal pump?[ 2024-04-29 ]

- How do I choose an industrial pump?[ 2024-05-14 ]

- Can a diaphragm pump pull a vacuum?[ 2024-04-29 ]

- diaphragm vs impeller pump[ 2024-05-04 ]