What is the lifespan of a pumping station?

The lifespan of a pumping station can vary greatly depending on a variety of factors, including design quality, construction materials, maintenance practices, and environmental conditions. Pumping stations play a crucial role in managing water and wastewater in both urban and rural settings. Given the importance of these facilities in sustaining water management systems, understanding their lifespan and how to maximize it is essential for any infrastructure project.

Factors Affecting Lifespan

Quality of Construction: The quality of materials and construction methods significantly affects a pumping station’s lifespan. Durable and corrosion-resistant materials like stainless steel or fiberglass can extend the life of the station.

Maintenance and Upkeep: Regular maintenance is key to ensuring the longevity of a pumping station. Properly maintained pumps and other components can last much longer.

Operational Conditions: Operating conditions such as water quality, temperature, and flow rates can influence the lifespan of a pumping station. For example, aggressive or corrosive water can reduce the life of some components.

Environmental Exposure: The surrounding environment, including factors such as humidity, salt exposure, and temperature fluctuations, can impact the durability and lifespan of the pumping station.

Design and Capacity: A pumping station designed to operate within its capacity will have a longer lifespan compared to one that is overburdened or stressed beyond its intended use.

Average Lifespan

On average, a well-constructed and properly maintained pumping station can last between 20 to 30 years, or even longer. This includes the mechanical and electrical components as well as the structural aspects. Replacement parts, particularly for pumps, may need to be updated every 5 to 10 years depending on usage.

Maximizing Lifespan

Routine Maintenance: Implementing a maintenance schedule that includes routine inspections and servicing of pumps, valves, and other components will extend the lifespan of the pumping station.

Quality Equipment: Investing in high-quality pumps and components at the outset can result in longer operational life and fewer breakdowns.

Upgrading Technology: Staying current with technological advances in pumping equipment can improve efficiency and extend the life of a pumping station.

Monitoring and Control: Modern pump stations with intelligent monitoring and control systems can help detect and address potential issues early, reducing downtime and maintenance costs.

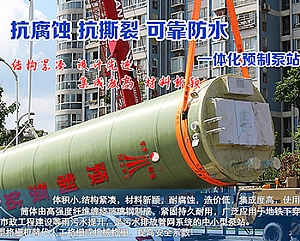

PEARL Pump's Integrated Prefabricated Pump Stations

PEARL Pump is a leading supplier of integrated prefabricated pump stations in China. Their advanced solutions are designed to provide reliable and efficient water and wastewater management, helping to maximize the lifespan of pumping stations.

Customizable Designs: PEARL Pump offers tailored pump station designs to meet the specific needs of your project, ensuring optimal performance and longevity.

Smart Pumping: Their intelligent pump stations feature real-time monitoring and control capabilities, allowing for efficient operation and early detection of potential issues.

Consultation: For more information on customized pump stations and pricing, contact PEARL Pump via:

Skype: +8615013488376

WhatsApp: +8615013488376

Email: shangzhengze@gmail.com

Conclusion

The lifespan of a pumping station is influenced by a combination of factors including construction quality, maintenance, operational conditions, and environmental exposure. With proper design, maintenance, and technology upgrades, the operational life of a pumping station can be significantly extended. PEARL Pump's integrated prefabricated pump stations offer advanced solutions that ensure reliable performance and longevity, making them a trusted partner for water and wastewater management needs. For expert advice and tailored pump station solutions, contact PEARL Pump today.

- What is the disadvantage of sewage pump?[ 2024-04-09 ]

- What type of pump is used for chemical transfer?[ 2024-05-20 ]

- Which pump is best for municipal water?[ 2024-06-12 ]

- diaphragm vs impeller pump[ 2024-05-04 ]

- Which pumps are used in industry? [ 2017-02-09 ]

- How are industrial pumps powered?[ 2024-04-15 ]

- What is the main advantage of submersible pump?[ 2024-05-18 ]

- What is a vacuum pump used for?[ 2024-05-01 ]

- What is a pipeline pump?[ 2024-04-11 ]

- What are 3 types of centrifugal pumps?[ 2024-04-15 ]

![[Wetland Park] FRP prefabricated pumping station](/UploadFiles/20191129134837863_s.jpg)